Mov'it brake kits, engineered in Achern Germany and tested on the autobahns and at nearby Hockenheim, offer automotive enthusiasts exceptional stopping performance, value and reliability. The pictures below show some of the steps required for the development and manufacturing of each kit.

1.

A new car, in this case a Bentley Arnage turbo, comes into Movit's new manufacturing facility.

It will be here a few days while Movit's engineer develops, fits and tests the components of these new front and rear applications.

New brake kits are being developed on a weekly basis giving Mov'it the widest selection of performance brake upgrades in the industry.

2.

Front and rear wheels removed reveal a stock brake system which cannot adequately stop this powerful and heavy car when driven to its potential.

Brake performance is more than just "red" painted calipers.

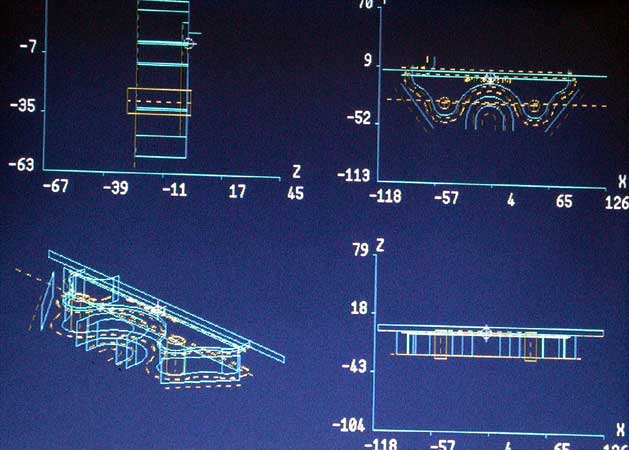

3.

The technical team meets to transform the "on-car" measurements into engineering drawings which will be used by the CNC equipment to machine the various kit components.

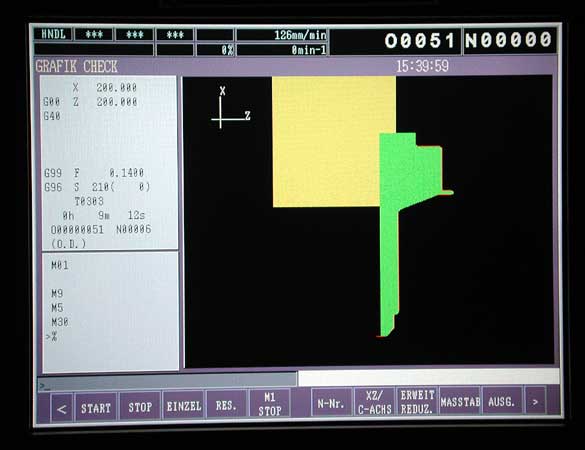

4.

CNC machines setup to commence production.

5.

Brake rotor hats start as a large cylindrical stock of 7075 aluminum.

CNC program ensures precise cutting and milling for each application component.

Manufactured parts are engraved with a unique Mov'it part number.

6.

Caliper brackets are machined from 4140 stock.

All manufactured steel components are zinc plated with yellow chromate for enhanced appearance and resistance to oxidation.

Part numbers are again engraved to uniquely identify each component.

7.

Movit's kit components come together with the highest quality "perforated" rotors and multi-piston calipers.

8.

Add the mounting hardware and a set of Fischer Hydraulik stainless steel brake lines and the Mov'it kit is ready for installation.

9.

The newly developed Mov'it kits are installed on the Bentley.

Front brakes consist of two monoblock 4-piston calipers (shown with custom scripting) on a 380mm rotor.

Rear kit consists of a 4-piston braking caliper and a small mechanical parking brake caliper around a 322mm rotor.

10.

All Mov'it kits sold in Europe must undergo a strict inspection by the TUV before the car is deemed roadworthy.

With this sort of scrutiny, component quality and proper fitment are a mandatory part of the engineering of every Mov'it brake kit.